Physicians have treated illness with inhaled remedies for thousands of years. The pressurized metered-dose inhalers (pMDIs) used today differ dramatically from the pipes, reeds, and pots used centuries ago, but the benefits of inhalation devices have stood the test of time.

As the inventors of the original pMDI, Kindeva draws on this legacy to develop the pulmonary & nasal innovations of the future. Let’s look at how far inhalation technology has come and what lies ahead.

PULMONARY & NASAL DELIVERY: ANCIENT TO MODERN TIMES

The first known reference to therapeutic aerosol delivery dates to about 1554 B.C. It describes Egyptians who were struggling to breathe fumes from heated plants. The delivery mechanism was a reed placed in a jar with a hole on top. Plants were placed under the jar on hot rocks, then people inhaled the medicinal vapors through the reed.

Incense burners, pipes, and funnels were popular mechanisms for inhaling herbs for medicinal and recreational use from about 1100 B.C. through the mid-1700s. These devices delivered a variety of inhaled treatments for asthma, cough, and other lung and nasal problems.

The rise of manufacturing during the Industrial Revolution led to the first mass-produced therapeutic aerosols. Nebulizers and dry powder inhalers (DPIs) were introduced during this time. English physician John Mudge coined the term “inhaler” in 1778. The Mudge inhaler, which looked like a tea pot with a long nozzle, was the first known commercialized inhaled device.

Dr. Auphon Euget-Les Bain developed the first atomizer in 1859 in France, but it involved directing a jet of mineral spring water against a spa wall. Nine years later, Jean Sales-Girons developed a portable version called the pulverisateur. The first plastic nebulizer arrived in the 1950s, shortly followed by other devices that used compressed gas.¹

KINDEVA DELIVERS THE FIRST METERED-DOSE INHALER

The early atomizers and nebulizers informed innovation through the 19th and 20th centuries. However, the pMDI’s debut advanced the landscape of therapeutic aerosol delivery. Kindeva introduced the first pMDI in 1956. Over the following decades, the industry experienced unprecedented growth, improving quality of life for hundreds of millions of individuals.

A second wave of innovation occurred in 1987 with the signing of the Montreal Protocol on Substances That Deplete the Ozone Layer. That landmark agreement regulates the production and consumption of nearly 100 ozone-depleting substances (ODS). Inhaler technology diversified with enhanced delivery efficiency, updated dry powder inhalers (DPIs), and more advanced nebulizers. Kindeva played a significant role in this innovation with the launch of Maxair in 1986 and the Maxair Autohaler in 1992.

THE ARRIVAL OF GREEN PROPELLANTS

The inhalation technology space went through a round of innovation involving the elimination of chlorofluorocarbons (CFCs). Kindeva broke new ground in this space by getting the first FDA-approved pMDI to use a hydrofluoroalkane (HFA) propellant approved and on the U.S. market in 1996. Since the last of the CFCs phased out of the U.S. around 2011, the industry has saved massive amounts of chlorine from entering the atmosphere and thereby greatly reduced the impact on both ozone depletion and atmospheric warming. But the journey continues as today’s pMDIs still use propellants with significant warming impact which can now be improved upon.

While the current HFA propellants have a much lower greenhouse impact than the original CFC propellants, standards change. The impact of these gases (over 1,000x that of CO2) is now unacceptable as the world works to reduce the human impact on the climate. The time has come for another change to the propellants used in pMDIs, and the industry is moving toward incorporating greener propellants into current and future products to create a sustainable future. Once again, Kindeva is leading the charge to bring these greener propellants to market.

GREENER COMBINATION PRODUCT MANUFACTURING

The move to the new generation of propellants requires significant investment in research and development (R&D) capacity to accommodate not only the increased demand for these sustainable and reformulated products, but also for whatever developments come next. Unlike some CDMOs that have moved away from pMDI development, we believe their ongoing optimization is essential to manufacturing more tomorrows for patients around the world.

With the introduction of greener HFA-152a and/or HFO-1234ze propellants, pharma companies have attractive alternatives, as these propellants have Global Warming Potentials (GWPs) that are 90% and 99.9% lower than P134a, the greenest pMDI propellant currently used.²

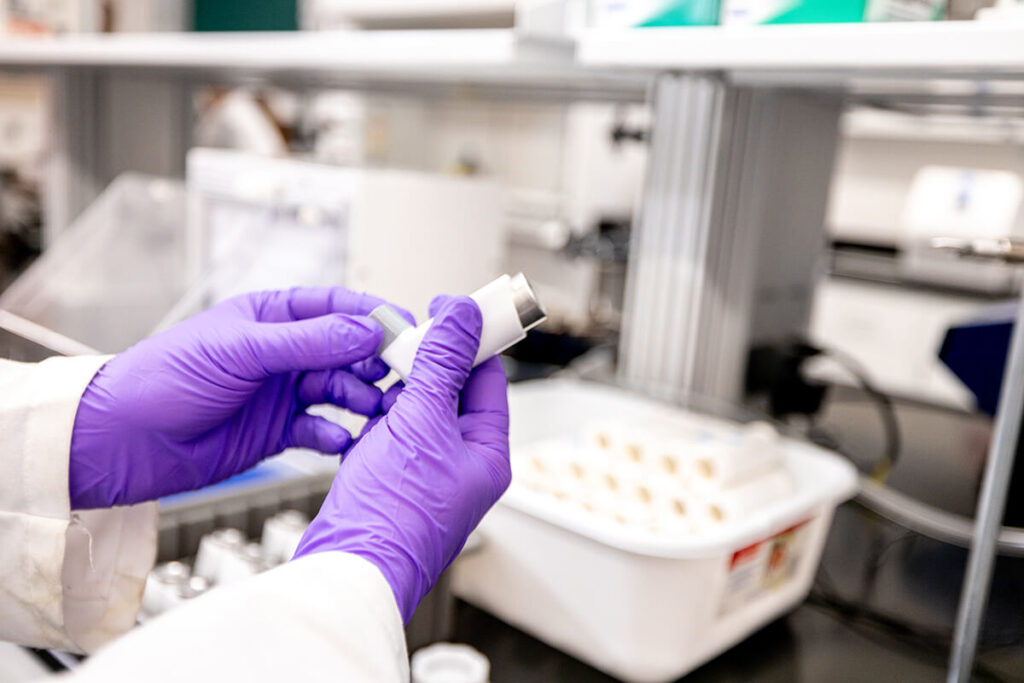

To accommodate emerging demand, we installed a pilot scale manufacturing line capable of filling inhalers with HFA-152a and/or HFO-1234ze propellants, with plans for further expansion. Clinical supply is already available, and we are currently installing a green propellant line set to begin commercial scale production in 2024, making us one of the first CDMOs to do so.

By helping sponsors bring greener products to market as early as possible without compromising safety and quality, we are helping to ease the transition to new HFAs without impacting the current availability of much-needed treatments. And once these greener products reach pharmacy shelves, odds are strong that physicians will prescribe the more sustainable option, driving market share.

THE NEXT INHALATION FRONTIER: BIOLOGICS

A relatively new type of product is coming to inhalation that early adopters centuries ago could not have imagined: biologics. Small molecule products will remain a staple for years to come, but we expect large molecule therapies to become more prevalent and likely to dominate the market. This is as true for inhaled therapies as it is other routes of administration; the approach for pMDI, DPI, nasal, etc., will be therapy specific as it is today — and we expect Kindeva to continue to be at the forefront of this innovative technology.

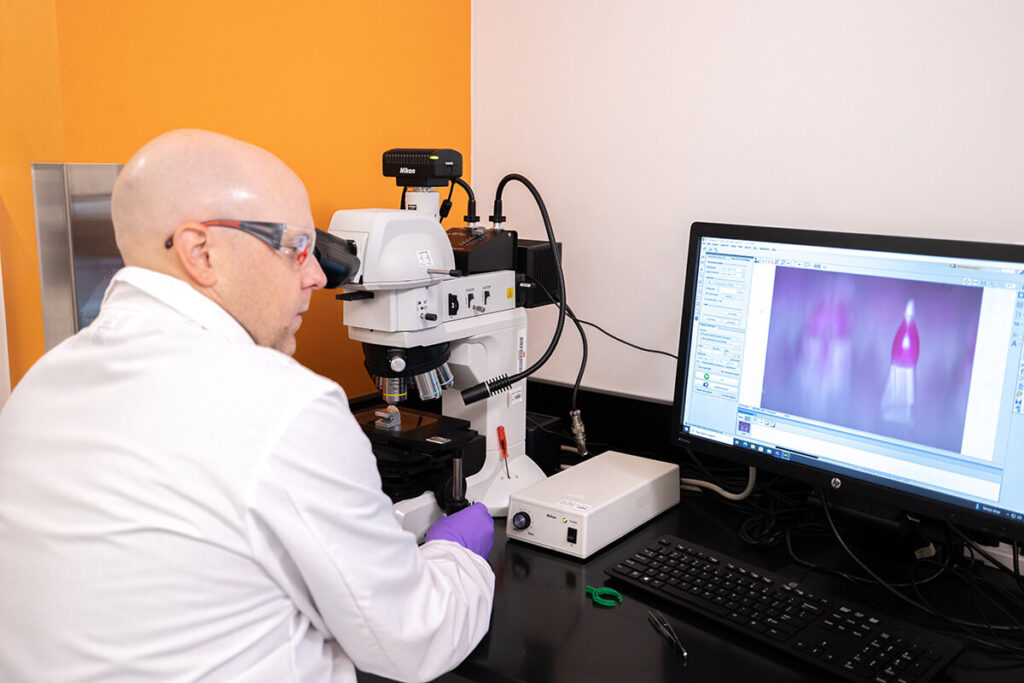

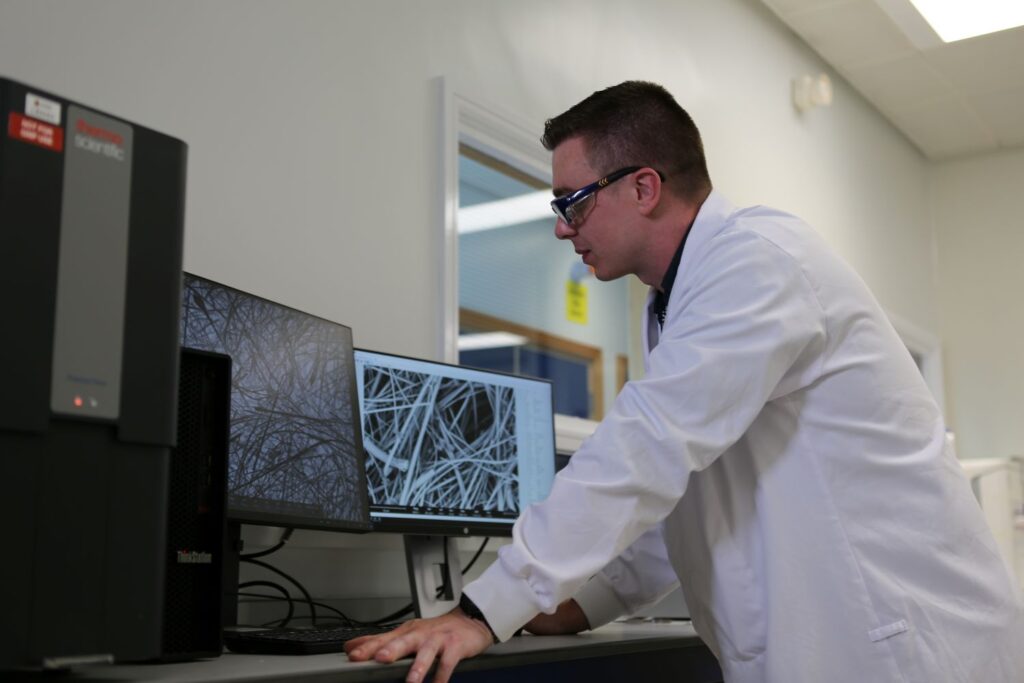

To develop and manufacture these products, changes to how materials are handled and analyzed will be essential. Evaluations of stability and the resulting drug-delivery adaptations will drive this next product evolution.

Kindeva is up to the challenge. With a long legacy of firsts in the pMDI space, we are ready to scale and adapt to the next wave of inhalation innovation.

Do you have questions about green propellants, inhaled biologics, or other pulmonary & nasal drug delivery platforms? We’d love to connect with you.

References

- Stein, S.W., & Thiel, C.G. “The History of Therapeutic Aerosols: A Chronological Review.” Journal of aerosol medicine and pulmonary drug delivery, 2017, Vol 30(1), pp 20-41.

- Fidler, L., Green, S., & Wintemute, K. “Pressurized metered-dose inhalers and their impact on climate change.” CMAJ: Canadian Medical Association Journal, 2022, Vol 194(2).

Related resources

Explore our other resources to discover valuable insights on the latest trends in drug delivery.

Beyond the contract: Driving transformational partnerships with manufacturing… and more

Achieving scientific breakthroughs is just one hurdle in today’s drug development and manufacturing process aimed at improving patient outcomes. Bringing a new therapy to market requires meticulous execution and clear communication at every step. Unfortunately, even the most groundbreaking scientific advancements can be delayed or even entirely abandoned due to poor performance from partners. This […]

Learn MoreWhy Kindeva: Analytical and regulatory services

Overcome complex analytical and regulatory challenges with a partner dedicated to your product’s success. Our specialist expertise helps you navigate testing, compliance, and quality to advance your project from concept to commercialization. Download our one-pager for a closer look at our integrated approach, including: An overview of our comprehensive, phase-appropriate analytical services. How our regulatory […]

Learn MoreCareer journeys blog 2: Oliver Ingham

In this latest installment, we meet Oliver Ingham, an analytical chemist whose curiosity and problem-solving skills have shaped his journey from academic research to coordinating analytical development services at Kindeva.

Learn MoreCareer journeys blog 1: Holly Dowdle

When Holly Dowdle first joined Kindeva as a student intern, she experienced a workplace that valued both curiosity and collaboration. It was an environment where asking questions was encouraged and development was part of everyday work, not something that happened on the sidelines.

Learn MoreA bridge between design and delivery: Exploring sterile fill finish integration for injectable product success

The global sterile injectable contract manufacturing market is experiencing rapid growth, driven by increasing demand for advanced biologics, glucagon-like peptide-1 (GLP-1) therapies and other injectables. These products pair drugs with delivery devices to support patient-centric care, but their manufacturing presents unique challenges. Programs often require specialized environments, such as cold-chain storage and low-volume fills, and […]

Learn MoreGoing beyond manufacturing: The Kindeva customer experience

Going beyond manufacturing: The Kindeva customer experience As development timelines tighten and product complexity grows, the quality of CDMO partnerships has transformed into a critical success factor. In today’s high-stakes landscape, drug developers need more than technical execution. They need partners who embed early, stay aligned and help navigate every phase of the product lifecycle. […]

Learn MoreBuilt for better tomorrows: How Bridgeton delivers for patients

Kindeva’s Bridgeton facility offers a purpose-built solution for the complex and evolving landscape of injectable drugs. The facility was specifically designed to address challenges in sterile injectable manufacturing, such as the siloed approaches that often separate core functions like formulation and fill finish. By co-locating these functions and operating within integrated systems, the Bridgeton model […]

Learn MoreBuilding confidence into complex drug-device programs with early analytical expertise

Drug-device programs are under pressure to do more, with tighter timelines, deeper scrutiny and increasing complexity. As teams move from concept through clinical and commercial phases, one challenge remains constant: ensuring products behave as intended, consistently and safely. That challenge gets more complicated as formulation, device mechanics, packaging and regulatory expectations converge. Whether developing an […]

Learn MoreWhat makes Bridgeton the perfect partner for your next sterile fill finish project?

The pharmaceutical sector is experiencing a significant increase in the demand for advanced biologics, biosimilar therapies and other sterile injectables. As a result, the global sterile injectables market is projected to grow from $632 billion in 2025 to $1.078 trillion by 2032, with a compound annual growth rate of 7.9% [1]. In response to this […]

Learn MoreLet’s transform tomorrow together

Every patient deserves a brighter tomorrow. As your strategic partner, we are dedicated to building your lasting legacy and helping you fast-track healthier tomorrows. You dream it, we deliver it.