Home / Knowledge hub /

Mastering USP 661.1 and 661.2: Kindeva Simplifies Your Path to Compliance

July 7, 2025

Understanding the evolution of USP <661.1> and <661.2>

In this blog, Jen Roark, Scientific Director of Injectables at Kindeva, breaks down the critical shift in pharmaceutical packaging standards ahead of the fast-approaching December 1, 2025, implementation deadline. She covers the history of USP <661.1> and <661.2>, the move to a risk-based framework, specific testing requirements for materials versus systems and how stakeholders can confidently navigate their compliance obligations.

It’s hard to believe that United States Pharmacopeia (USP) General Chapters <661.1> Plastic Materials of Construction and <661.2> Plastic Packaging Systems for Pharmaceutical Use have been in existence for well over ten years now. These chapters were first published in Pharmacopeial Forum PF 39(5) for public comment in September-October 2013, and both chapters first became official in USP 39/NF34 on May 1, 2016. However, implementation of these chapters was delayed for several years due to feedback from industry stakeholders who called for more time to gear up to meet the new requirements. Significant changes in the testing protocols for plastic packaging systems were instituted through these “new” USP General Chapters in comparison to the historical requirements detailed in USP <661> Plastic Packaging Systems and their Materials of Construction. Until the official implementation date of December 1, 2025, USP <661> remains the standard unless packaging suppliers or drug product manufacturers choose early adoption of USP <661.1> and <661.2>.

A risk-based framework for packaging evaluation

The changes implemented in USP <661.1> and <661.2> promote a risk-based approach to the selection and evaluation of plastic packaging systems (3). These chapters emphasize physicochemical characterization of plastic materials prior to proceeding with biologic reactivity testing to “replace, reduce, and/or refine animal use in testing” (4). In addition, these USP General Chapters align with standards such as Ph. Eur. 3.2.2 Plastic Containers and Closures for Pharmaceutical Use and ISO 10993 Biological Evaluation of Medical Devices to streamline and facilitate international regulatory compliance. The goal of these chapters is to improve patient safety and product efficacy by assessing the packaging materials in direct contact with the drug product to ensure that the materials meet strict safety standards (3). To summarize, any polymeric vial, syringe, cartridge, bottle, or other plastic packaging system that comes into direct contact with a drug product must comply with these requirements.

A three-stage qualification strategy for packaging systems

USP General Chapter <1661> Evaluation of Plastic Packaging Systems for Pharmaceutical Use and Their Materials of Construction provides further guidance on how to apply USP <661.1> and <661.2>. Specifically, it discusses a three-stage process for the characterization and qualification of plastic packaging systems and their materials of construction. The first stage involves a material assessment of the plastic resins that are used to make container components that eventually become the packaging system. Here, different resins are characterized, screened, and then selected based on the test results generated as per USP <661.1>. Next is the packaging system assessment and qualification stage. Here, the packaging system (e.g., bottle and cap) that is in direct contact with the drug product is tested for certain extractables as per USP <661.2> with reference to <1663> Assessment of Extractables Associated with Pharmaceutical Packaging/Delivery Systems. In the final stage of the process, the packaged product is tested for leachables and assessed for the potential impact of the leachables profile on drug product quality and safety. This testing is performed as per USP <661.2> with reference to USP <1664> Assessment of Drug Product Leachables Associated with Pharmaceutical Packaging/Delivery Systems (5).

USP <661.1>: Testing and characterization of plastic resins

So, what are the specific requirements of the testing associated with each of the chapters and the intended applications for USP <661.1> and <661.2>? USP <661.1> focuses on the various types of plastic resin materials that are used to fabricate packaging system components. For the material of construction (i.e., resin) to be well-characterized for its intended use, several characteristics of the resin material must be established analytically. The specific characteristics of the resin material include:

- Identity as per USP <854> Mid-Infrared Spectroscopy through comparison of the IR generated spectrum of the resin material against the USP reference standard for the material.

- Biological reactivity as per USP <87> Biological Reactivity Tests, In Vitro, Elution Test for Polymeric Materials. USP <87> indicates that further analysis as per USP <88> Biological Reactivity Tests, In Vivo is performed only if the sample does not meet the requirements of the Elution Test. USP <661.1> does not require Biological Reactivity testing for oral and topical dosage forms.

- Physicochemical properties as prescribed in USP <661.1>:

o UV Absorbance as per USP <857> Ultraviolet-Visible Spectroscopy

o Acidity/Alkalinity by titration as prescribed in USP <661.1>

o Total Organic Carbon (TOC) as per USP <643> Total Organic Carbon - Extractable elements as needed (refer to USP <1661>) to identify:

o Intentional elemental additives such as catalysts and processing aids

o Unintentional elemental additives such as processing contaminants and ingredient impurities - Composition (plastic additives likely to be present) as prescribed in USP <661.1> and determined by TLC, HPLC/UV or GC/FID as per USP <621> Chromatography.

The chapter informs the testing of the following plastic resins used to manufacture the packaging systems:

- Cyclic olefins

- Polyamide 6

- Polycarbonate

- Polyethylene

- Polyethylene terephthalate and polyethylene terephthalate G

- Poly(ethylene-vinyl acetate)

- Polypropylene

- Polyvinyl chloride

- Polyvinyl chloride, plasticized

- Unaddressed materials – resins not included in the chapter are considered “unaddressed materials” and must be tested in the same manner comparable to the tests for the resins that are specified in the chapter.

Who tests what? Clarifying stakeholder obligations

USP <661.1> states that “individual plastic materials of construction are considered to be well characterized if they meet the requirements in this chapter OR are used in a packaging system that meets the requirements in [USP <661.2>]” (6). Typically, it is the responsibility of the manufacturer of the plastic packaging components or the packaging/delivery systems for pharmaceutical use to perform testing as per USP <661.1>.

However, if a drug product manufacturer sources fully fabricated components or an entire plastic packaging system from a supplier, the drug product manufacturer is not required to obtain the resin from the supplier and perform testing as per USP <661.1>. Rather, the drug product manufacturer is responsible for testing the fully fabricated components or the entire plastic packaging system as per USP <661.2>. The reason is simple – the fully fabricated components or entire plastic packaging systems have been exposed to all manufacturing processes and additives at that point and will be subject to extractables and leachables assessments per USP <1663> and <1664> as part of the testing requirements in USP <661.2>.

USP <661.2>: Testing fully fabricated packaging systems

USP <661.2> informs the testing of plastic components and packaging systems that will contain a pharmaceutical or biological drug product throughout its lifecycle (i.e., storage, distribution, and administration) (7). As similarly stated in USP <661.1>, components and/or the packaging systems are well-characterized if they meet the requirements of USP <661.2>, and are chemically suitable for their intended use if the following requirements have been met for the components and/or the packaging systems:

- Physicochemical properties as prescribed in USP <661.2>:

o UV Absorbance

o Acidity/Alkalinity by titration as prescribed in USP <661.2>

o Total Organic Carbon (TOC) as per USP <643> Total Organic Carbon - Biological reactivity as per USP <87> Elution Test for Polymeric Materials. USP <87> indicates that further analysis as per USP <88> Biological Reactivity Tests, In Vivo is performed only if the sample does not meet the requirements of the Elution Test. USP <661.2> does not require Biological Reactivity testing for oral and topical dosage forms.

- Chemical suitability assessment, which comprises a risk-based extractables and leachables assessment as per USP <1663> and USP <1664>

- Functionality (Spectral Transmission if light protection is necessary) as prescribed in USP <661.2> and as per USP <857>.

Remember, the purpose of this chapter is to characterize the components or packaging systems. If any of the physicochemical tests of the components or packaging systems by USP <661.2> do not meet the acceptance criteria, justification for use could be made via the Chemical Suitability Assessment.

No direct contact vs. non-interacting materials: What’s the difference?

If there is little or no chance of a material and the drug product interacting, the material is considered a “non-interacting” material and does not have to be tested by USP <661.1> and <661.2>. Note that there is a difference between the terms “no direct contact” and “non-interacting”. A material is considered to have “no direct contact” with a drug product when the packaging material and the drug product do not come into direct physical contact with each other. An example of “no direct contact” would be a foil overpouch with an adhesive label into which a flexible plastic container is placed. However, the foil overpouch could potentially interact with the packaged drug product because substances from the foil overpouch could permeate through the flexible plastic container. An example of a “non-interacting” material is the adhesive label because the foil overpouch is impermeable, so no substances from the label could permeate through the foil overpouch into the flexible plastic container (5).

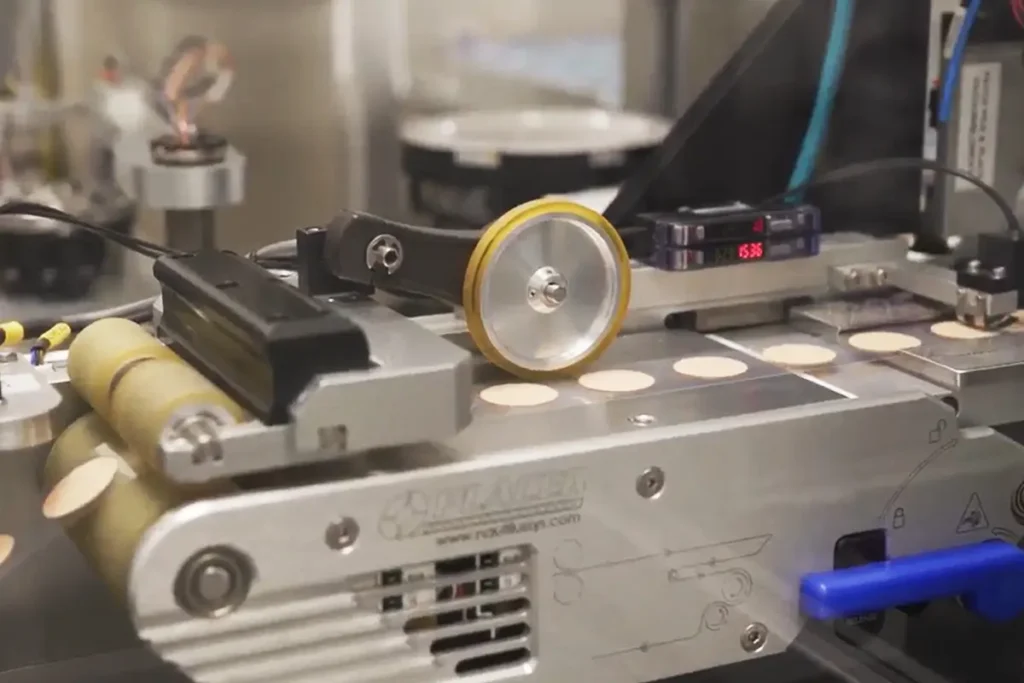

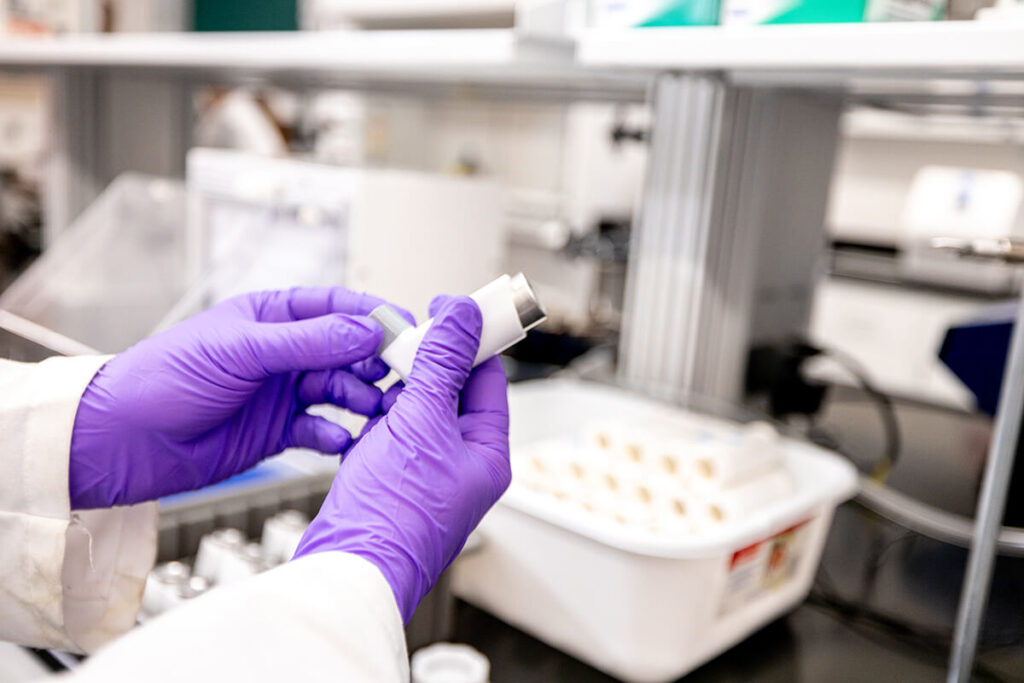

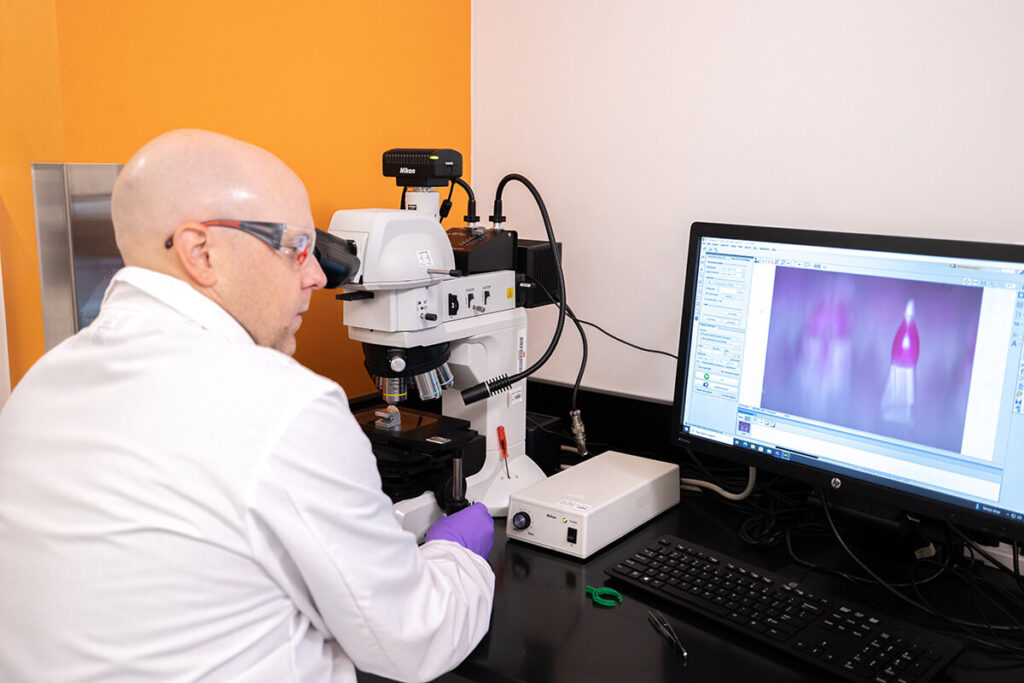

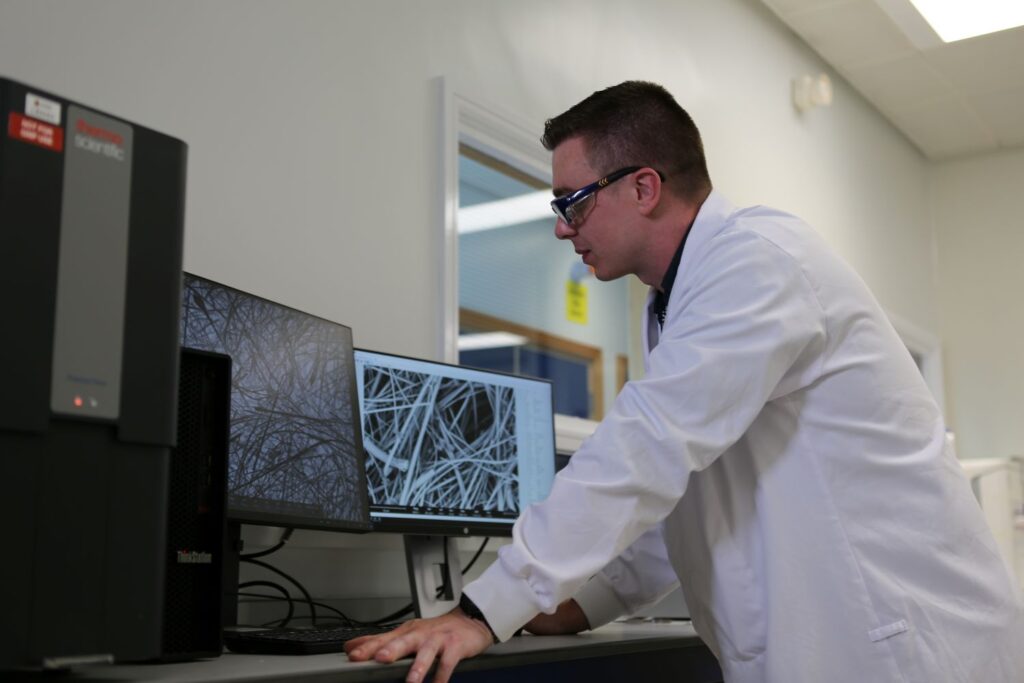

Packaging confidence, powered by analytical expertise

Navigating these USP General Chapters can be complex, but Kindeva’s Analytical Services team offers the expertise and infrastructure to support compliance with confidence. Our analytical laboratories are fully equipped to perform all tests prescribed in USP <661.1> and <661.2>, and our staff of highly qualified scientists have extensive experience with extractables and leachables assessments as per USP <1663> and <1664> guidelines.

Visit our website at Analytical Testing Services | Kindeva CDMO today! Our Business Development Representatives look forward to discussing your analytical testing needs.

References:

- USP. 661_rb_notice.pdf

- USP. Plastic Packaging Systems and Their Materials of Construction <661>. In: USP NF. Rockville, MD: USP; August 1, 2024

DOI: https://doi.org/10.31003/USPNF_M99420_05_01 - Albert D. (2020), “A practical approach to analytical chemistry of medical devices”. Biocompatibility and Performance of Medical Devices.

https://doi.org/10.1016/B978-0-08-102643-4.00005-7 - U.S. Department of Health and Human Services; Food and Drug Administration (FDA); Center for Devices and Radiological Health (CDRH). Use of International Standard ISO 10993-1, “Biological evaluation of medical devices – Part 1: Evaluation and testing within a risk management process” – Final Guidance – Transcript October 12, 2023

- USP. Evaluation of Plastic Packaging Systems for Pharmaceutical Use and Their Materials of Construction <1661>. In: USP-NF. Rockville, MD: USP; November 1, 2020

DOI: https://doi.org/10.31003/USPNF_M9293_06_01 - USP. Plastic Materials of Construction <661.1>. In: USP-NF. Rockville, MD: USP; December 1, 2025

DOI: https://doi.org/10.31003/USPNF_M8008_13_01 - USP. Plastic Packaging Systems for Pharmaceutical Use <661.2>. In: USP-NF. Rockville, MD: USP; December 1, 2025

DOI: https://doi.org/10.31003/USPNF_M8009_06_01

Related resources

Explore our other resources to discover valuable insights on the latest trends in drug delivery.

Career journeys blog 4: Grace Guo

In this story, we meet Grace Guo, Manager of Client Portfolio Relationship Management, whose pathway at Kindeva has grown through clear communication, strategic thinking and a strong focus on people.

Learn MoreThe next leap in skin-based drug delivery: How dermal delivery platforms are transforming tomorrows for patients

Skin-based drug delivery is gaining attention as patients and healthcare systems look for treatments that support at-home administration and remove the need for needle-based injections. As this shift accelerates, developers are investing in technologies that improve usability without compromising performance. These platforms are opening new possibilities for therapies that rely on reliable, patient-preferred delivery. A […]

Learn MoreWebinar | A Bridge to the Future of Aseptic Manufacturing: A Pharma 4.0 Case Study

Growing demand for high-quality sterile fill finish capacity is putting pressure on development timelines and supply programs across the industry. As expectations for Annex 1 alignment, agility and data-driven control rise, partners need facilities designed to keep pace with evolving requirements. In this on-demand webinar, Chad Hafer, Director of Technical Operations, Aseptic Fill Finish at […]

Learn MoreCareer journeys blog 3: Lauren Harrison

In this story, we meet Lauren Harrison, a formulation scientist who began her path as an apprentice and has spent the last decade building a career rooted in curiosity, hands-on learning and collaboration.

Learn MoreNavigating the transition to next-generation propellants for pMDIs | On-demand webinar

Regulators, health systems and patients expect meaningful progress on sustainability. For pressurized metered dose inhalers (pMDIs), this means planning the transition to low global warming potential (low-GWP) next-generation propellants (NGPs) now, not at the end of the decade. In this webinar with Pharmaceutical Technology, Craig Somerville, Senior Vice President of Kindeva’s pMDI business unit, shares […]

Learn MoreBeyond the contract: Driving transformational partnerships with manufacturing… and more

Achieving scientific breakthroughs is just one hurdle in today’s drug development and manufacturing process aimed at improving patient outcomes. Bringing a new therapy to market requires meticulous execution and clear communication at every step. Unfortunately, even the most groundbreaking scientific advancements can be delayed or even entirely abandoned due to poor performance from partners. This […]

Learn MoreWhy Kindeva: Analytical and regulatory services

Overcome complex analytical and regulatory challenges with a partner dedicated to your product’s success. Our specialist expertise helps you navigate testing, compliance, and quality to advance your project from concept to commercialization. Download our one-pager for a closer look at our integrated approach, including: An overview of our comprehensive, phase-appropriate analytical services. How our regulatory […]

Learn MoreCareer journeys blog 2: Oliver Ingham

In this latest installment, we meet Oliver Ingham, an analytical chemist whose curiosity and problem-solving skills have shaped his journey from academic research to coordinating analytical development services at Kindeva.

Learn MoreCareer journeys blog 1: Holly Dowdle

When Holly Dowdle first joined Kindeva as a student intern, she experienced a workplace that valued both curiosity and collaboration. It was an environment where asking questions was encouraged and development was part of everyday work, not something that happened on the sidelines.

Learn MoreLet’s transform tomorrow together

Every patient deserves a brighter tomorrow. As your strategic partner, we are dedicated to building your lasting legacy and helping you fast-track healthier tomorrows. You dream it, we deliver it.