Home / Knowledge hub /

The Kindeva Advantage: Setting the Gold Standard for Elemental Impurities Testing

August 19, 2025

In this blog, Jen Roark, Scientific Director of Injectables at Kindeva, explores the challenges of controlling elemental impurities in drug products. She breaks down the risks and regulatory guidelines outlined in USP <232> and ICH Q3D, then takes a deep dive into the findings of a recent PQRI interlaboratory study that highlights the complexities of accurate testing. Lastly, she covers how Kindeva’s expert approach to sample preparation and ICP-MS analysis sets the gold standard for mitigating these risks and ensuring patient safety.

Elemental impurities (EIs), such as arsenic, cadmium, lead, and mercury, can pose serious patient health risks such as organ damage, cancer, or even neurological issues due to their toxicity. EIs can also cause the aggregation, fragmentation, or misfolding of proteins, impacting the efficacy and stability of biologics. For these reasons, EIs in drug products must be monitored and controlled. Mitigating the risk of EIs in pharmaceutics and biologics is vital to drug product quality and safety. To address these risks, both USP General Chapter <232> Elemental Impurities – Limits and ICH Q3D(R2) Guideline for Elemental Impurities provide detailed guidance on limits for the permitted daily exposure (PDE) of certain EIs of concern. It is important for drug product sponsors and manufacturers to understand the risks associated with the EIs that pose toxicity concerns, the sources, the limits, and how to analyze for the presence of them in their drug products to ensure safety.

ICH Q3D indicates that because EIs do not provide any therapeutic benefit, they must be controlled (1). The PDE limits for each EI are set based on toxicological risk and the bioavailability of the EI, which is associated with the route of administration of the drug product (1). As a result, there are different PDEs for the same EI for oral, parenteral, inhalation, and cutaneous and transcutaneous drug products (2). In addition, the sources of EIs often vary, depending on the route of administration. These sources include but are not limited to:

- Residual catalysts added intentionally to the material

- EIs present in the drug substance or excipients but not intentionally added

- Interactions with processing/manufacturing equipment

- Leachables from the container closure systems

ICH Q3D divides EIs into three classes (Class 1, Class 2A/2B and Class 3), with the most toxic elements included in Class 1 and Class 2A. The Class 1 elements are arsenic, cadmium, lead, and mercury; and the Class 2A elements include cobalt, nickel, and vanadium (1).

Because the ICH Q3D Class 1 and Class 2A elements are pervasive, these elements must be considered in every risk assessment (2). The control strategy for EIs in a particular drug product should be set considering variability in the amounts of EIs in their sources and in the drug product, in addition to variability associated with the analytical method used for EI detection and quantification (2). On March 9, 2025, the Product Quality Research Institute (PQRI) published a study in the Journal of Trace Elements and Minerals entitled The Product Quality Research Institute elemental impurity interlaboratory study: Results and implications for industry. The paper describes an interlaboratory study conducted among twenty-one participating ICP-MS laboratories to assess sample preparation and analysis variability in the measurement of the ICH Q3D Class 1 and Class 2A EIs in standardized samples. The PQRI working group recognized that very few studies have been conducted to evaluate interlaboratory proficiency with testing for EIs in pharmaceutical drug products as per USP General Chapter <233> Elemental Impurities – Procedures at the limits specified in USP General Chapter <232> and the ICH Q3D guidelines. PQRI’s goal was to address key challenges with the implementation of these guidelines in testing laboratories (3).

In the study, standardized samples were provided to each participating ICP-MS testing laboratory for analysis. The ICH Q3D Class 1 and Class 2A EIs are most often considered in risk assessments due to their toxicity and probability of occurrence in drug products (3). For this reason, tablet samples and samples made using pharmaceutically relevant raw materials were prepared to contain the Class 1 and Class 2A EIs at three concentrations comparable to the maximum PDEs for EIs in an orally administered drug, as outlined in USP

<232>: 30% PDE (the control threshold), PDE, and 300% PDE (3).

The raw material samples included:

- Lactose

- Magnesium Aluminum Silicate

- Microcrystalline Cellulose

- Red Ferric Oxide

- Silicon Dioxide Standard containing As, Co, Hg

- Silicon Dioxide Standard containing Cd, Ni, Pb

- Starch

- Stearic Acid

At each participating ICP-MS laboratory, the standardized samples were prepared for elemental analysis using either a single reaction chamber (SRC) or an individually pressurized vessel (IPV) microwave system to digest the samples. Both a “moderately aggressive exhaustive extraction” and a “highly aggressive total digestion” of the samples were performed for comparison (3). The “exhaustive extraction” was performed using concentrated nitric acid with the addition of 1000 μg/mL gold inorganic standard, then the sample was diluted, and hydrochloric acid was added for a final acid concentration of 2% nitric acid and 2% hydrochloric acid. The microwave system parameters used for the exhaustive extraction comprised a temperature ramp to 175°C over a period of 10 minutes, hold the temperature at 175°C for 10 minutes, then cool to <60°C in the microwave system (3).

The “total digestion” was performed using a mixture of concentrated hydrochloric acid, concentrated nitric acid, concentrated phosphoric acid, and fluoroboric acid prepared from a mixture of concentrated hydrofluoric acid and boric acid. The sample was then diluted to a final acid concentration of 2% nitric acid, 2% hydrochloric acid, and 0.2% hydrofluoric acid. The microwave system parameters comprised a temperature ramp to the maximum safe temperature over a period of 25 minutes, hold at the maximum safe temperature for 20 minutes, then cool to <60°C in the microwave system (3).

The sample preparation parameters described above were developed specifically for the PQRI study not unlike the way we, the Analytical Services team at Kindeva, develop test methods for elemental analysis. Depending on the goal of the test, we routinely prepare ICP-MS samples by performing either an “exhaustive extraction” or a “total digestion” using our CEM Corporation Blade Microwave Digestion System equipped with IPV. We also have the capability to use hydrofluoric acid to facilitate the total digestion of tricky inorganic samples, such as talc, titanium dioxide, or silicon dioxide.

In the PQRI study, each ICP-MS testing laboratory was required to conduct signal optimization and daily instrument performance checks as per the manufacturer instructions for their respective models of ICP-MS systems used for testing (3). Laboratories could also use their own internal standards and collision cell gases of choice (3). Standardized analytical isotopes were used to perform a linear calibration of the Class 1 and Class 2A elements using aqueous acid matrix-matched standards, and the ICP-MS testing parameters used for analysis were as standardized as possible among the participating laboratories (3).

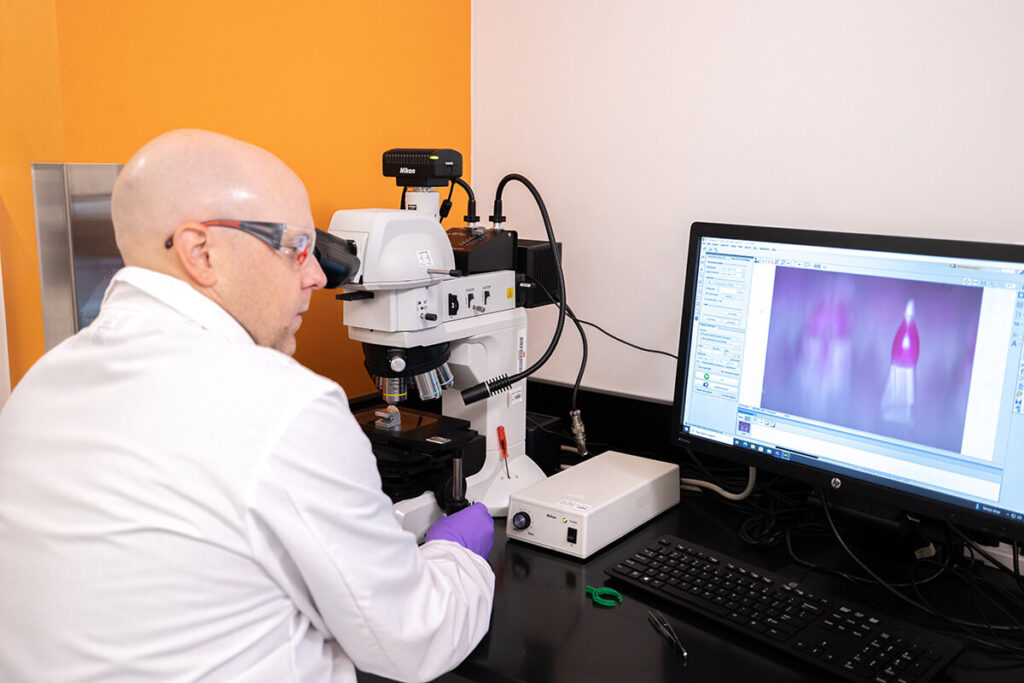

At Kindeva, we employ our Agilent 7900 model ICP-MS systems for elemental analysis with either helium or hydrogen collision gas options. As standard procedure, we perform system suitability testing with a series of matrix-matched linear calibration standards prepared from commercially available NIST-traceable stock standards prior to sample analysis to ensure that the ICP-MS system can accurately detect and quantify all targeted elements from parts per trillion up to parts per thousand in the test sample.

Overall, the results of the PQRI interlaboratory study were favorable, demonstrating accuracy and reproducibility for most targeted EIs among the various laboratories. Of all elements tested, the measured values for mercury and vanadium in the tablet samples were the most variable, exhibiting the lowest recoveries against the reference values (3). Since mercury is a volatile element, the low recoveries observed for the tablet samples suggested a potential loss of mercury in those samples over time (3).

Variations in vanadium observed during the analysis of the raw materials were mostly due to false positives from the formation of chlorine monoxide cations (ClO+) in samples with no or very little vanadium as determined by the reference laboratory (3). These false positives emphasize the importance of optimizing the collision cell parameters to reduce interferences to acceptable levels. Kindeva’s ICP-MS experts are experienced with ways to stabilize mercury in sample preparations for accurate and precise detection, and to mitigate interferences associated with the detection of targeted elements by ICP-MS. Other results generated during the PQRI study suggested that the measured values for the EIs in the raw material samples were less variable, and the recoveries against the reference values were more accurate in the raw materials than in the tablet samples. In addition, the recoveries of elements from the Silicon Dioxide Standard raw material were better for the total digestion method than the exhaustive extraction method. The study indicated that intralaboratory (within-lab) variability was lower than interlaboratory (between-lab) variability, meaning that the test results by ICP-MS for the targeted EIs were more repeatable within the same laboratory than they were reproducible across multiple external laboratories (3).

Achieving the quantitation limits required in USP General Chapters <232> and <233> can be challenging, but the Analytical Services team at Kindeva makes it easy. Our GMP and FDA-audited analytical laboratory is fully equipped to perform elemental impurities testing as per USP <232> and <233> by ICP-MS. Our staff of highly qualified scientists have extensive experience with extractables testing as per USP General Chapter <1663> Assessment of Extractables Associated with Pharmaceutical Packaging/Delivery Systems; and with leachables testing as per <1664> Assessment of Drug Product Leachables Associated with Pharmaceutical/Packaging Systems for all EIs listed in the ICH Q3D guidelines, as well as other elements that may be of interest such as iron, manganese, and zinc.

To learn how you can optimize your analytical testing and drug development with Kindeva’s specialized expertise and integrated solutions, connect with our experts today.

References:

- International Council for Harmonization of Technical Requirements for Pharmaceuticals for Human Use. ICH Harmonized Guideline. Guideline for Elemental Impurities Q3D(R2). Final version Adopted on 26 April 2022

- USP. Elemental Impurities – Limits <232>. In: USP-NF. Rockville, MD: USP; May 1, 2024 DOI: https://doi.org/10.31003/USPNF_M5192_03_01

- Harrington, James M. et al, The Product Quality Research Institute elemental impurity interlaboratory study: Results and implications for industry, Journal of Trace Elements and Minerals 12 (2025) 100227 DOI: https://doi.org/10.1016/j.jtemin.2025.100227

Related resources

Explore our other resources to discover valuable insights on the latest trends in drug delivery.

Why Kindeva: Analytical and regulatory services

Overcome complex analytical and regulatory challenges with a partner dedicated to your product’s success. Our specialist expertise helps you navigate testing, compliance, and quality to advance your project from concept to commercialization. Download our one-pager for a closer look at our integrated approach, including: An overview of our comprehensive, phase-appropriate analytical services. How our regulatory […]

Learn MoreAnalytical testing strategy and approach for combination products

Download Kindeva’s presentation from the Pharma Ed Combination Products Summit for insights on how to ensure your combination product’s compliance with regulatory requirements through analytical testing.

Learn MoreYour analytical services partner

Support your combination product throughout its life cycle with expert analytical services from Kindeva Drug Delivery. Backed by over a century of combination product expertise, we have unrivaled know-how to ensure your therapy’s compliance and quality. Discover our wide range of analytical services, including: Analytical method development & validation Stability testing & storage Extractables and […]

Learn MoreLet’s transform tomorrow together

Every patient deserves a brighter tomorrow. As your strategic partner, we are dedicated to building your lasting legacy and helping you fast-track healthier tomorrows. You dream it, we deliver it.