Home / Knowledge hub /

Opportunities and challenges for inhalation drug delivery of biologics

July 18, 2024

The biopharmaceutical industry is experiencing a transformative shift toward the development of biologic drugs, particularly in the realm of inhaled drug delivery. A significant portion of biologics, approximately 10%, are being developed for respiratory delivery.1 This burgeoning pipeline includes a diverse array of molecules and targets. However, this approach also presents unique formulation and device engineering challenges to ensure effective delivery.

Unlocking therapeutic potential through inhaled drug delivery

While most current vaccines and other biologics are administered via injection, delivering these large molecules directly to the respiratory tract through inhalation offers several compelling advantages. The mucosal surfaces of the lungs and nasal cavity serve as prime entry points for many pathogens, making inhaled delivery an intuitive approach for inducing a localized response.

For vaccines specifically, inhaled administration can effectively stimulate all three arms of the immune system: cellular immunity to eliminate infected cells, humoral immunity to produce circulating antibodies, and critically, mucosal immunity comprising secretory antibodies that provide the first line of defense at mucosal surfaces.2 This integrated immune activation at the pathogen’s entry point could enable more robust and durable protection.3

Beyond vaccines, inhaled biologics present opportunities across a wide range of respiratory indications. By delivering therapeutics directly to the target tissues, higher localized drug concentrations can potentially be achieved with lower systemic exposure. Needle-free administration also addresses the common fear of injections, which may be a barrier to treatment adherence.4

From a product perspective, inhaled powder formulations of biologics may offer extended stability at room temperature, eliminating cold chain requirements. This could significantly increase accessibility and enable self-administration.

Overcoming technical challenges

While the potential benefits of inhaled biologics are considerable, the physicochemical properties of biologic drugs, such as their molecular size, charge, and conformational stability, present unique formulation challenges. Achieving efficient pulmonary or nasal delivery necessitates careful optimization of the drug formulation and inhalation devices.

Given the large doses involved, nebulizers and dry powder formulations are often the most suitable delivery methods.5 Each approach has its own intricacies in terms of formulation design, manufacturing processes, and device engineering considerations.

Nebulizers

Nebulizers, which aerosolize liquid drug formulations into inhalable droplets or particles, represent a promising delivery modality for inhaled biologics, particularly for larger molecule and higher dose applications. They are also well-suited for fast development. However, this approach also faces unique technical hurdles.

One major consideration is the potential for protein instability and degradation due to the stresses involved in the nebulization process. Jet nebulizers, which rely on compressed gas to atomize the liquid, expose proteins to high shear forces as the drug recirculates through the nebulizer multiple times before being emitted as aerosol droplets. This can compromise the structural integrity of delicate biologic molecules. Vibrating mesh nebulizers provide a gentler alternative, generating aerosols as the liquid is extruded through a vibrating mesh aperture in a single pass. Vibrating mesh nebulizers also excel in terms of efficiency, with less dead volume and therefore less potential to waste the drug product.

Achieving efficient lung deposition of the nebulized aerosol is another key challenge. The ideal aerodynamic particle size range is around 3-6 microns, resulting in 60-80% regional deposition in the lungs.6 Larger droplets may be filtered out in the upper airways, while smaller ones run the risk of being exhaled. However, optimizing droplet size requires a trade-off between higher mean lung deposition and lower variability.7

In order to overcome these challenges, a focus on efficient dose delivery is essential. Synchronizing the delivery of the aerosol with breath, delivering during inspiration and thus avoiding product loss during exhalation, is a potential solution. Additionally, ensuring aerosols are within the respirable range can help improve dose delivery efficiency and consistency.

Dry powder formulations

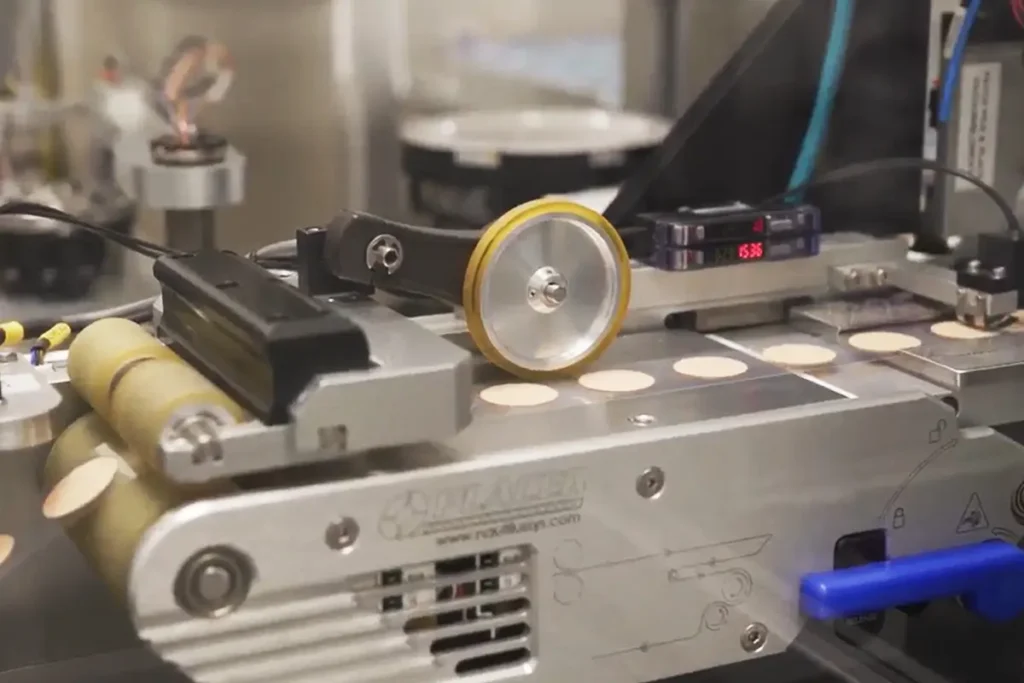

For molecules that are sensitive to moisture, dry powder is a more suitable route than nebulizers. Dry powder formulations are often produced through spray drying. This process is particularly suited for producing inhaled biologics due to its efficiency and ability to handle delicate biologics (even living cells). By optimizing spray drying processes, manufacturers can produce low-density, dispersible powders that can be delivered efficiently with simple device mechanisms.

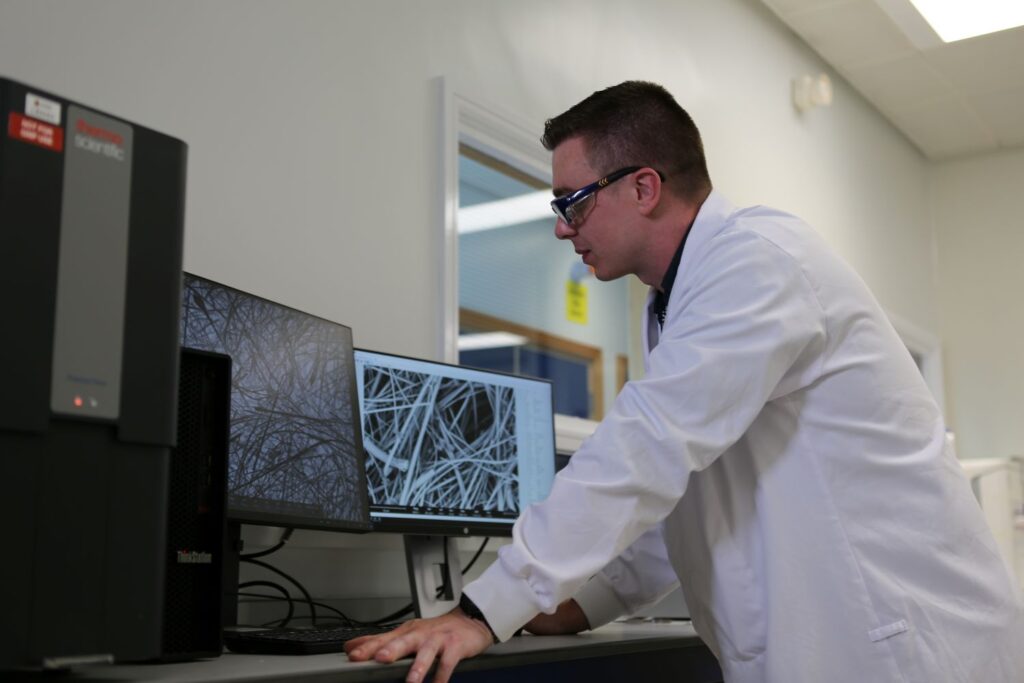

The spray drying process introduces several physical stresses, including heat. Evaporative cooling maintains the droplet at just above room temperature, completing liquid evaporation within a few milliseconds and keeping the protein below the inlet temperature. As the particle heats, it approaches the outlet temperature, making this parameter one of the most relevant for minimizing the impact on protein structure.8

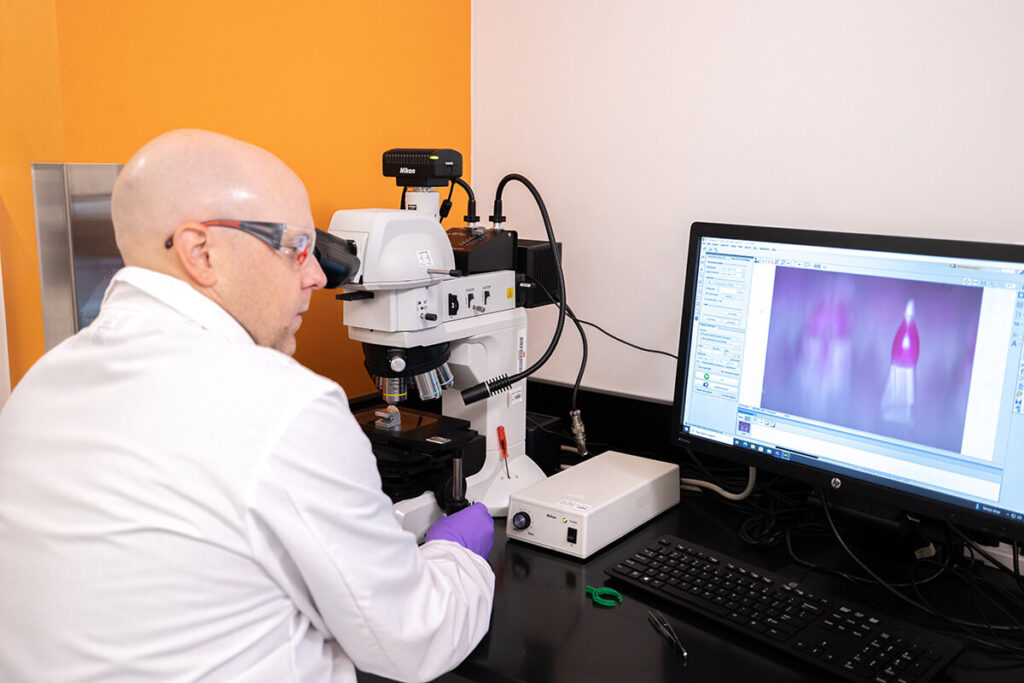

The creation of core-shell particles is a pivotal aspect of spray drying to mitigate stability issues.9 Shell-forming excipients, which are responsible for the micromeritic properties of the powder, migrate to the surface during drying, encapsulating the protein within the particle’s core. This configuration enhances protein stability by minimizing exposure to the air-liquid interface. Within the core, where the protein is intended to reside, stability is further maintained using glass-forming agents, buffers, antioxidants, and other stabilizers.

By controlling feedstock composition and evaporation rates, it is possible to tailor the size and structure of particles in dry powder formulations. The shell-forming excipient plays a critical role in determining particle size and morphology. Spray-dried core-shell particles can reduce oligomer formation, contributing to their stability advantages and potentially minimizing immunogenicity.

To improve lung deposition and minimize oropharyngeal deposition, it is essential to manage the aerodynamic diameter of the particles. Targeting primary particles with a corrugated surface, facilitated by shell-forming excipients, helps achieve higher lung doses, as smooth particles tend to result in lower total lung deposition.10 This corrugated morphology, along with controlled particle size, allows for manipulation of the aerodynamic properties to bypass deposition in the mouth and throat.

Proper packaging also plays a crucial role in maintaining the stability of dry powder formulations. Ensuring a tight moisture barrier is vital for extending the shelf life of these products. The stability and performance of the spray-dried powders are maintained at room temperature, unlike liquid formulations that require refrigeration, offering logistical benefits.

Harnessing the potential of inhaled biologics

Inhalation drug delivery may enhance therapeutic efficacy, minimize side effects, and/or improve patient compliance. However, the journey from concept to market involves overcoming significant technical challenges, particularly in formulation and device engineering.

To dive deeper into considerations for inhaled biologics, we invite you to download Kindeva’s recent webinar on the topic. The presentation features insights from John Patton, Head Kindeva SAB, Kindeva Drug Delivery; Keith Ung, Director and Bay Area Site Head, Kindeva Drug Delivery; Andy Clark, President and General Manager, Aerogen Pharma Corporation; and Jeff Weers, Chief Technology Officer, Cystetic Medicines, Inc.

Download your copy to discover a wide range of biologics expertise.

References

1 Gavtash, B. Kindeva and Pharmacircle. (2024).

2 Holmgren, J., and Czerkinsky, C. Mucosal immunity vaccines. Nature

Medicine Supplement. Volume 11:S45-54 (2005).

3 Waldeman, R.H., et al. Aerosol Delivery, But Not IM Injection, of Adenovirus-Vectored Tuberculosis (TB) Vaccine Induced Respiratory Mucosal Immunity in Humans. (1969) JAMA 207:520-524.

4 McLenon, J., and Rogers, M.A.M. The fear of needles: A systematic review and meta‐analysis of 35 studies. J Adv Nurs. (2019);75:30–42.

5 Clark, A.R. Half a Century of Technological Advances in Pulmonary Drug Delivery: A Personal Perspective. Frontiers in Science. (2022).

6 Clark, A.R. The use of laser diffraction for the evaluation of aerosol clouds generated by medical nebulizers. International Journal of Pharmaceutics 115 (1995): 69-78.

7 Clark, A.R. Essentials for aerosol delivery to term and pre-term infants. Ann Transl Med. 2021 Apr; 9(7): 594.

8 Snyder, H., and Lechuga-Ballesteros, D. Spray Drying: Theory and Pharmaceutical Applications, Lachmann and Liebermann, 3rd ed., 1008.

9 Vehring, R. Pharmaceutical particle engineering via spray drying. Pharm Res. (2004); 25:999-1022.

10 Ung, K., Weers, J., Huang, D., et al. Targeted delivery of spray-dried formulations to the lungs. WO (2017).

Related resources

Explore our other resources to discover valuable insights on the latest trends in drug delivery.

The next leap in skin-based drug delivery: How dermal delivery platforms are transforming tomorrows for patients

Skin-based drug delivery is gaining attention as patients and healthcare systems look for treatments that support at-home administration and remove the need for needle-based injections. As this shift accelerates, developers are investing in technologies that improve usability without compromising performance. These platforms are opening new possibilities for therapies that rely on reliable, patient-preferred delivery. A […]

Learn MoreWebinar | A Bridge to the Future of Aseptic Manufacturing: A Pharma 4.0 Case Study

Growing demand for high-quality sterile fill finish capacity is putting pressure on development timelines and supply programs across the industry. As expectations for Annex 1 alignment, agility and data-driven control rise, partners need facilities designed to keep pace with evolving requirements. In this on-demand webinar, Chad Hafer, Director of Technical Operations, Aseptic Fill Finish at […]

Learn MoreCareer journeys blog 3: Lauren Harrison

In this story, we meet Lauren Harrison, a formulation scientist who began her path as an apprentice and has spent the last decade building a career rooted in curiosity, hands-on learning and collaboration.

Learn MoreNavigating the transition to next-generation propellants for pMDIs | On-demand webinar

Regulators, health systems and patients expect meaningful progress on sustainability. For pressurized metered dose inhalers (pMDIs), this means planning the transition to low global warming potential (low-GWP) next-generation propellants (NGPs) now, not at the end of the decade. In this webinar with Pharmaceutical Technology, Craig Somerville, Senior Vice President of Kindeva’s pMDI business unit, shares […]

Learn MoreBeyond the contract: Driving transformational partnerships with manufacturing… and more

Achieving scientific breakthroughs is just one hurdle in today’s drug development and manufacturing process aimed at improving patient outcomes. Bringing a new therapy to market requires meticulous execution and clear communication at every step. Unfortunately, even the most groundbreaking scientific advancements can be delayed or even entirely abandoned due to poor performance from partners. This […]

Learn MoreWhy Kindeva: Analytical and regulatory services

Overcome complex analytical and regulatory challenges with a partner dedicated to your product’s success. Our specialist expertise helps you navigate testing, compliance, and quality to advance your project from concept to commercialization. Download our one-pager for a closer look at our integrated approach, including: An overview of our comprehensive, phase-appropriate analytical services. How our regulatory […]

Learn MoreCareer journeys blog 2: Oliver Ingham

In this latest installment, we meet Oliver Ingham, an analytical chemist whose curiosity and problem-solving skills have shaped his journey from academic research to coordinating analytical development services at Kindeva.

Learn MoreCareer journeys blog 1: Holly Dowdle

When Holly Dowdle first joined Kindeva as a student intern, she experienced a workplace that valued both curiosity and collaboration. It was an environment where asking questions was encouraged and development was part of everyday work, not something that happened on the sidelines.

Learn MoreA bridge between design and delivery: Exploring sterile fill finish integration for injectable product success

The global sterile injectable contract manufacturing market is experiencing rapid growth, driven by increasing demand for advanced biologics, glucagon-like peptide-1 (GLP-1) therapies and other injectables. These products pair drugs with delivery devices to support patient-centric care, but their manufacturing presents unique challenges. Programs often require specialized environments, such as cold-chain storage and low-volume fills, and […]

Learn MoreLet’s transform tomorrow together

Every patient deserves a brighter tomorrow. As your strategic partner, we are dedicated to building your lasting legacy and helping you fast-track healthier tomorrows. You dream it, we deliver it.