Home / Knowledge hub /

Building confidence into complex drug-device programs with early analytical expertise

October 29, 2025

Drug-device programs are under pressure to do more, with tighter timelines, deeper scrutiny and increasing complexity.

As teams move from concept through clinical and commercial phases, one challenge remains constant: ensuring products behave as intended, consistently and safely.

That challenge gets more complicated as formulation, device mechanics, packaging and regulatory expectations converge. Whether developing an inhaler with a next-generation propellant (NGP) or scaling an autoinjector, these interactions must be understood and managed from the start.

That’s where Analytical Services comes in.

Why analytical thinking needs to start early

When analytical testing is viewed as a final checkpoint, issues can often appear too late to fix without delay and cost. This could be a shift in aerodynamic particle size distribution, the emergence of an unknown leachable from a container closure system, or an autoinjector’s extrusion force drifting out of specification after temperature cycling.

Most of these risks can be addressed before they impact timelines, but only if analytical services are integrated from the outset of the project.

By designing studies tailored to a product’s delivery route, formulation and lifecycle phase, teams will be better placed to identify risks before they become problems and generate data that informs real, impactful decisions.

What we test, and why it matters

Kindeva’s analytical services cover pulmonary, nasal, injectable and dermal systems, including emerging formats like microneedle array patches, with capabilities built for both traditional and complex delivery formats.

For pulmonary and nasal products, we evaluate formulation-device compatibility, aerodynamic behavior, particle distribution, and in-vitro bioequivalence (IVBE). These studies are especially critical when transitioning to NGPs, where demonstrating consistent performance without full clinical studies can be a regulatory expectation.

Injectables, including autoinjectors and prefilled syringes, are tested for container closure integrity, extractables and leachables, functional performance (break-loose, glide, safety activation) and impurity profiles.

Dermal systems require a different focus: adhesive performance over time, release rate behavior under various storage conditions and permeation characteristics through skin analogues.

These studies aren’t off-the-shelf; they’re designed in context. For a product in early development, that might mean stress-testing storage conditions. For one approaching commercial scale, it could mean validating a method to detect micro-level degradation over time.

Meeting new development demands

As product categories evolve and regulatory expectations deepen, we’ve adapted our capabilities to meet new development needs across:

In-vitro bioequivalence (IVBE)

When inhalation products must demonstrate therapeutic equivalence, but patient studies are impractical or unnecessary, IVBE becomes a critical path.

These in-vitro methods allow teams to compare drug delivery behavior through dissolution, particle size, and formulation performance against established references.

For pulmonary products, it’s a way to generate meaningful equivalence data without introducing patient variability.

Functional performance testing under real conditions

Functional testing has long been used to verify design intent. However, for validation, especially with rising regulatory expectations, it must reflect actual use.

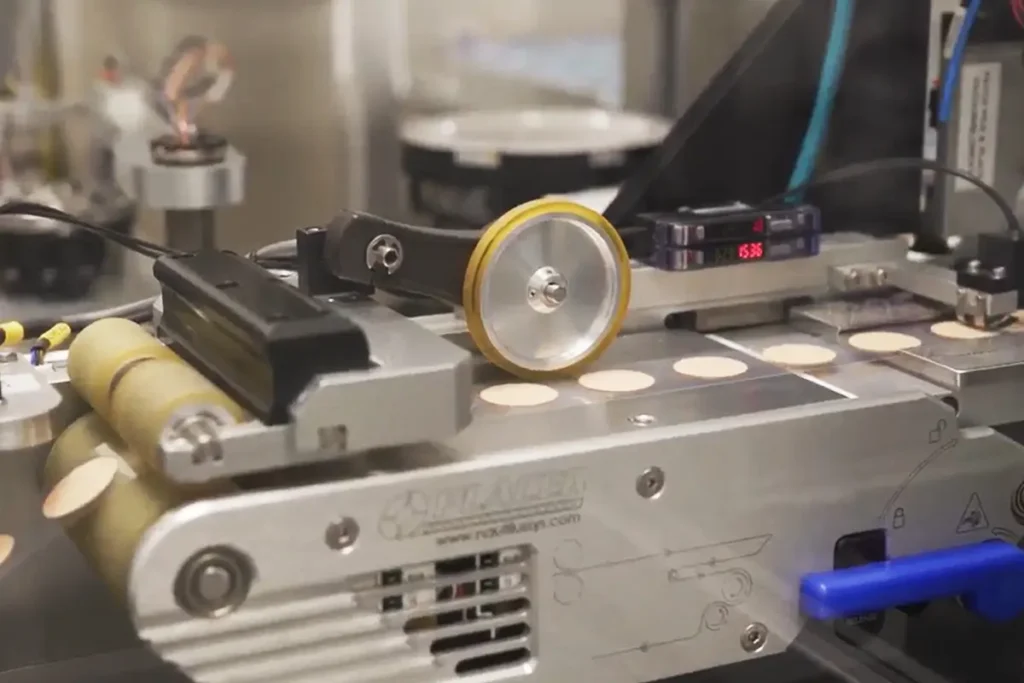

At Kindeva, device performance testing now occurs in a cGMP environment, using product-filled systems.

That shift enables more accurate simulation of real-world forces (break-loose, extrusion, and deliverable volume), with data that better supports regulatory review and commercial readiness.

Testing for biologic-device combinations

As more large molecule therapies are delivered through device systems, the need for biologics-specific analytics increases. We’ve expanded protein testing capabilities across two sites:

- Our site in Bridgeton, MO, supports QC and batch release.

- Our site in Woodbury, MN, supports validation and stability testing

This setup helps reduce handoffs and maintain analytical consistency from preclinical through market launch.

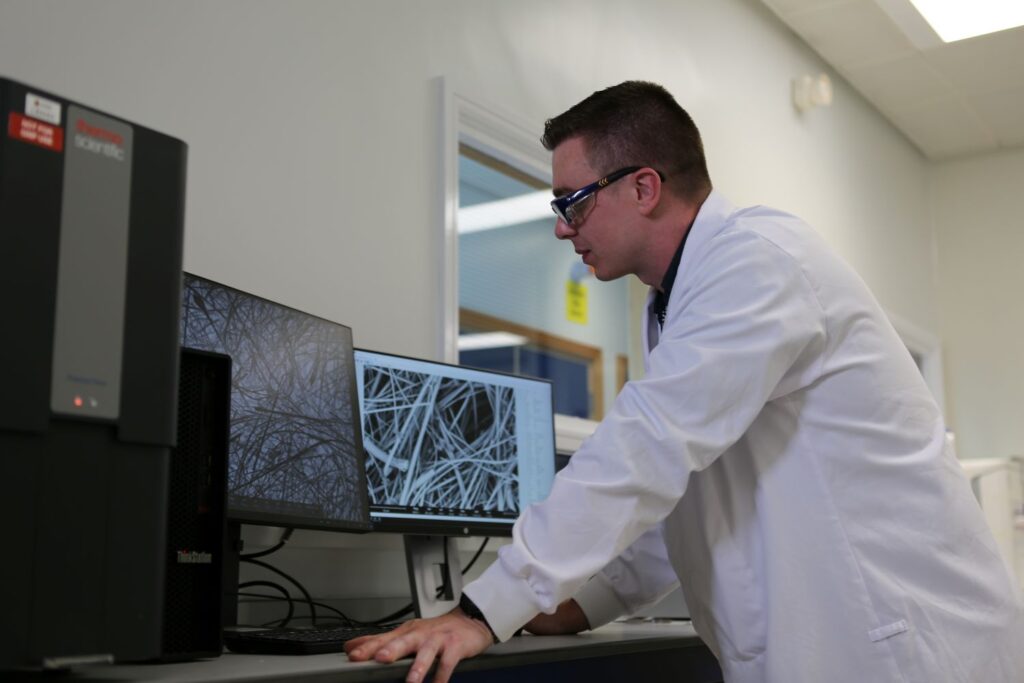

Computational fluid dynamics (CFD) modeling

Some interactions, such as regional deposition in lungs or fluid flow through an injector, can’t easily be seen or tested physically. That’s where in-silico modeling becomes practical.

Our CFD capabilities simulate spray dynamics, deposition, mixing and pressure-flow characteristics. These tools help engineering teams explore “what if” scenarios, validate design choices or spot risk before it becomes costly.

Trusted testing, tailored to the path ahead

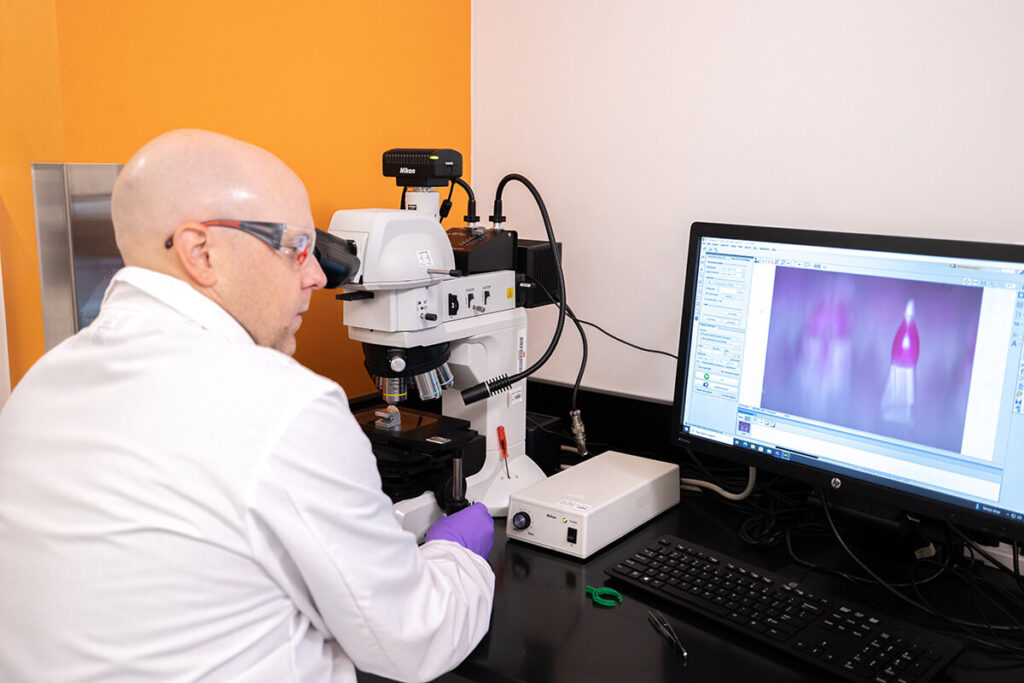

Effective analytical testing isn’t just about the capabilities, but the confidence behind them. That’s why our services are delivered by a team of over 60 scientists with deep, hands-on experience across formulation types, delivery routes and regulatory environments. We’ve developed and validated more than 300 analytical methods, supporting complex programs from early development through commercial readiness.

Our analytical labs in Woodbury, MN are FDA-registered, cGMP-compliant and DEA-licensed. Our analytical labs in Loughborough, UK, are EMA-certified. Both are built to handle complex combination product development from feasibility through to commercial readiness, with environmental cycling chambers, validated stability storage and instrumentation for both compendial and advanced analytics.

We support every major delivery route with specialized analytical expertise in:

- Pulmonary: Deep experience in pMDIs, in-vitro bioequivalence and NGPs

- Nasal: Proven regulatory track record across U.S. and EU markets

- Injectables: Precision testing to support analytical roadmaps for complex drug-device programs

- Dermal: End-to-end support with unique adhesive performance insights and NDA/ANDA experience

Our analytical systems are designed to adapt, ensuring the data you generate moves your product forward, phase by phase.

Your analytical services partner

The value of an analytical partner isn’t just in lab reports, it’s in how those results are interpreted and applied.

At Kindeva, we work as an extension of your development team. Our scientists help flag patterns, troubleshoot anomalies and build method validation strategies aligned with your regulatory path.

When decisions rely on data, the strength of your analytical approach can determine how far and how fast your product can go.

Learn more about our advanced analytical capabilities at: https://www.kindevadd.com/cdmo-services/analytical/

Related resources

Explore our other resources to discover valuable insights on the latest trends in drug delivery.

Career journeys blog 4: Grace Guo

In this story, we meet Grace Guo, Manager of Client Portfolio Relationship Management, whose pathway at Kindeva has grown through clear communication, strategic thinking and a strong focus on people.

Learn MoreThe next leap in skin-based drug delivery: How dermal delivery platforms are transforming tomorrows for patients

Skin-based drug delivery is gaining attention as patients and healthcare systems look for treatments that support at-home administration and remove the need for needle-based injections. As this shift accelerates, developers are investing in technologies that improve usability without compromising performance. These platforms are opening new possibilities for therapies that rely on reliable, patient-preferred delivery. A […]

Learn MoreWebinar | A Bridge to the Future of Aseptic Manufacturing: A Pharma 4.0 Case Study

Growing demand for high-quality sterile fill finish capacity is putting pressure on development timelines and supply programs across the industry. As expectations for Annex 1 alignment, agility and data-driven control rise, partners need facilities designed to keep pace with evolving requirements. In this on-demand webinar, Chad Hafer, Director of Technical Operations, Aseptic Fill Finish at […]

Learn MoreCareer journeys blog 3: Lauren Harrison

In this story, we meet Lauren Harrison, a formulation scientist who began her path as an apprentice and has spent the last decade building a career rooted in curiosity, hands-on learning and collaboration.

Learn MoreNavigating the transition to next-generation propellants for pMDIs | On-demand webinar

Regulators, health systems and patients expect meaningful progress on sustainability. For pressurized metered dose inhalers (pMDIs), this means planning the transition to low global warming potential (low-GWP) next-generation propellants (NGPs) now, not at the end of the decade. In this webinar with Pharmaceutical Technology, Craig Somerville, Senior Vice President of Kindeva’s pMDI business unit, shares […]

Learn MoreBeyond the contract: Driving transformational partnerships with manufacturing… and more

Achieving scientific breakthroughs is just one hurdle in today’s drug development and manufacturing process aimed at improving patient outcomes. Bringing a new therapy to market requires meticulous execution and clear communication at every step. Unfortunately, even the most groundbreaking scientific advancements can be delayed or even entirely abandoned due to poor performance from partners. This […]

Learn MoreWhy Kindeva: Analytical and regulatory services

Overcome complex analytical and regulatory challenges with a partner dedicated to your product’s success. Our specialist expertise helps you navigate testing, compliance, and quality to advance your project from concept to commercialization. Download our one-pager for a closer look at our integrated approach, including: An overview of our comprehensive, phase-appropriate analytical services. How our regulatory […]

Learn MoreCareer journeys blog 2: Oliver Ingham

In this latest installment, we meet Oliver Ingham, an analytical chemist whose curiosity and problem-solving skills have shaped his journey from academic research to coordinating analytical development services at Kindeva.

Learn MoreCareer journeys blog 1: Holly Dowdle

When Holly Dowdle first joined Kindeva as a student intern, she experienced a workplace that valued both curiosity and collaboration. It was an environment where asking questions was encouraged and development was part of everyday work, not something that happened on the sidelines.

Learn MoreLet’s transform tomorrow together

Every patient deserves a brighter tomorrow. As your strategic partner, we are dedicated to building your lasting legacy and helping you fast-track healthier tomorrows. You dream it, we deliver it.