Home / Knowledge hub /

What happens when large-scale manufacturing meets full-service CDMO capabilities?

November 16, 2023

In the ever-evolving pharmaceutical and biotechnology industries, the demand for seamless integration between large-scale manufacturing and full-service CDMO capabilities has never been more critical. In this article by Chad Hafer, discover how access to the process, range of services, and capacity is crucial to minimize risk, lower costs, and streamline timelines through every stage of drug development.

The Value of a Comprehensive CDMO

Although you can certainly choose to source various needs from different CDMOs, there is a real benefit to having a comprehensive partner whose capabilities span the full spectrum of development and manufacturing. For one, each knowledge transfer between companies during the process introduces an opportunity for delays. Having support through every stage of your product’s life cycle can save you valuable time and get your product to market sooner.

There’s also the matter of cost; having a dedicated full-service partner reduces your expenses. If you go back and forth between two different suppliers, you will incur additional overhead and transportation costs, plus costs for additional validation studies. Comparatively, when you have guidance throughout the clinical trial process and move into full-scale manufacturing, you can start with small volumes and scale-up to very large volumes, all under one roof with less expense.

Risk mitigation and audit-readiness are also major benefits to having a single-source strategic partner. When every stage of the development and manufacturing process happens with a full-service CDMO, there is only one supplier to audit. This allows you to minimize regulatory burden and simplify quality processes. Ultimately, this also benefits the patients who rely on these products and need to trust that they are safe and effective every time. The more consistent the process is, the better it is for sponsors as well as patient populations.

Proven Experience Lowers Your Risk

Over time, organizations learn what works and what does not; this breadth of hands-on experience cannot be replicated. Experience makes it easier for your CDMO partner to identify challenges and find innovative solutions, lowering risk for you.

Comprehensive Capabilities Meet Your Needs at Every Product Stage

A single-source partner needs to have extensive capabilities that cover the full breadth of your development and manufacturing needs — from formulation and small development test trials to sterile fill-finish, large-scale commercial manufacturing, and finished device packaging and inspection — and they must be able to scale these capabilities as you grow.

Enhanced Automation Control Through Isolators

As industry has taken notice of the benefits of isolators, their use has increased steadily over the past decade. However, many facilities have retrofitted their lines, using a combination of isolators and traditional aseptic filling, such as RABS. This partial implementation of automation controls puts facilities on par with the latest industry standards. However, exceeding those standards to shape the CDMO of tomorrow takes more. Transitioning to a full isolator line requires a substantial investment of time and resources, but the benefits are significant.

Isolators provide enhanced automation and engineering controls compared to traditional aseptic filling. Minimizing operator intervention is at the intersection of quality, safety, and mitigating financial concerns. The more automated a process can be, the more consistent it is — which is essential when it comes to manufacturing products relied upon to work effectively every time.

Ensuring Annex I Compliance

Annex I went into effect in August of 2023 with the goal of reflecting the latest advancements in sterile manufacturing. However, regulators have noted that it is going to take time for most facilities to become fully compliant. Facilities that are just beginning the process of switching to new technology can expect to wait 16 to 18 months from order to fabrication, meaning it will be years before these sites become cGMP compliant.

Partnering with a proactive CDMO with facilities that already fulfill Annex I requirements, such as our new Bridgeton, MO, location, ensures compliance from day one.

A Closer Look at Bridgeton

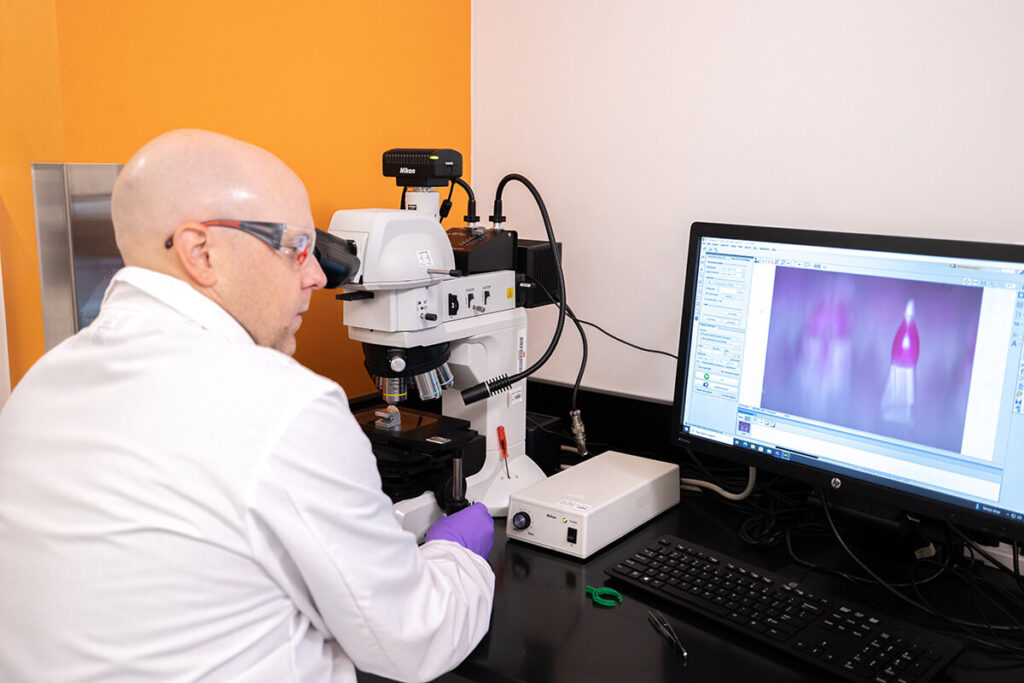

Kindeva’s Bridgeton site is unique in the combination product manufacturing space in that we have made isolator technology the standard, without any exceptions. We understand the importance of automation and compliance, and we’ve designed our entire facility around enhanced controls, even incorporating additional insights from suppliers to further reduce variability and operator interference.

Every piece of equipment and every process incorporates our experience and what we have heard from regulators and customers about industry needs and preferences. The result is a facility that has the latest innovations at the ready to fulfill your product requirements.

Large-Scale Manufacturing With Full-Service Capabilities Is Within Reach

By partnering with a full-service CDMO, you unlock greater efficiency and quality through every stage of your combination product’s life span. This reduces risk and provides more value for you and, ultimately, for your patients.

Visit Kindeva to explore our capabilities and see how we can help you bring your therapy into the world.

Related resources

Explore our other resources to discover valuable insights on the latest trends in drug delivery.

The impact of inlet design on HFA-152a pMDI drug delivery

When assessing aerodynamic particle size distribution (APSD) using the Next Generation Impactor (NGI), throat model selection can significantly influence drug deposition outcomes. Accurate deposition data is essential for optimising pMDI design and ensuring consistent, effective drug delivery to patients. Recent research by our pulmonary/pMDI experts—Aaron Taylor, Chad Haraldson, and Stephen Stein at Kindeva—explores how United […]

Learn MoreEvaluating extractables in low-GWP pMDI formulations

As the pharmaceutical industry advances toward low global warming potential (GWP) propellants like HFA152a and HFO1234ze(E), understanding material compatibility becomes critical, especially when it comes to leachables from common device components. In a recent evaluation, a group of pulmonary experts at Kindeva assessed the extractable levels associated with various polybutylene terephthalate (PBT) suppliers in pressurized […]

Learn MoreThe three key trends that will most impact drug development in 2025

The speed of change in the drug development and manufacturing sector requires its stakeholders to be proactive in understanding and addressing key trends and directions the industry is taking. As a global market of considerable size and significance, the value of which is anticipated to grow from $589.06 billion in 2024 to $632.71 billion in […]

Learn MoreMicroneedle array patch characterization recording

Microneedle array patches (MAPs) have the potential to transform delivery of medications and vaccines. While this innovative drug delivery format could result in improved efficiency across a wide range of therapeutics, it also brings critical challenges. To successfully move from concept to commercialization, MAP manufacturers must consider scalability, regulatory compliance, and other complexities. In this […]

Learn MoreMicroneedle array patch characterization presentation

Microneedle array patches (MAPs) are a transformative innovation in drug delivery, with the potential to redefine how medications and vaccines reach patients. MAPs promise a simpler, more effective way to deliver a wide range of therapeutics, but their journey from concept to commercialization is filled with critical challenges. From scaling manufacturing to ensuring regulatory compliance, […]

Learn MoreAddressing top tech transfer challenges

Technology transfer represents a critical bridge between development and commercial manufacturing. This complex process — moving product and process knowledge between development and manufacturing teams or between different manufacturing sites — demands precision at every stage. The implications of technology transfer extend beyond knowledge sharing. Each decision during this process directly impacts manufacturing efficiency, regulatory […]

Learn MoreTech transfer commercial manufacturing mindset

Technology transfer (tech transfer) moves product and process knowledge between teams or partners and acts as a crucial bridge between ideation and commercialization. Especially for complex products like sterile injectables, a smooth tech transfer process is essential. In this white paper, discover valuable strategies to embrace a commercial manufacturing mindset from day one. Download your […]

Learn MoreHFA152a green propellant capabilities

With evolving regulations and a growing push for sustainability, switching pressurized metered-dose inhalers (pMDIs) to green propellants is becoming increasingly essential. One of the most promising low global warming potential (GWP) options is HFA152a. In this white paper, we share insights on transitioning to HFA152a. Download your copy to discover: An overview of sustainability regulations […]

Learn MoreSterile product introduction and tech transfers in a crowded market

The tech transfer landscape for sterile products is increasingly complex, with pressure to reduce time to market. Find out how to navigate common challenges and avoid costly delays or oversights in this presentation from our Director, Client Portfolio & Relationship Management, Kim Brown. Download your copy to explore: Benefits of a commercial manufacturing mindset How […]

Learn MoreLet’s transform tomorrow together

Every patient deserves a brighter tomorrow. As your strategic partner, we are dedicated to building your lasting legacy and helping you fast-track healthier tomorrows. You dream it, we deliver it.